Serpentine channel drawing figure by Clark et al. (2018)

FLUIDS SERPENTINE MICROMIXER INSTRUMENT PLATFORM

Unbox, set up and start your experiments right away

No need for active mixing device as magnetic stir bar

Good homogeneity at the channel outlet

Microfluidic flow micromixing

Mixing up to four fluids in a microfluidic channel has never been easier using the microfluidic serpentine micromixer Pack for many applications like immunoassays, mixing PCR solutions, or chemical synthesis!

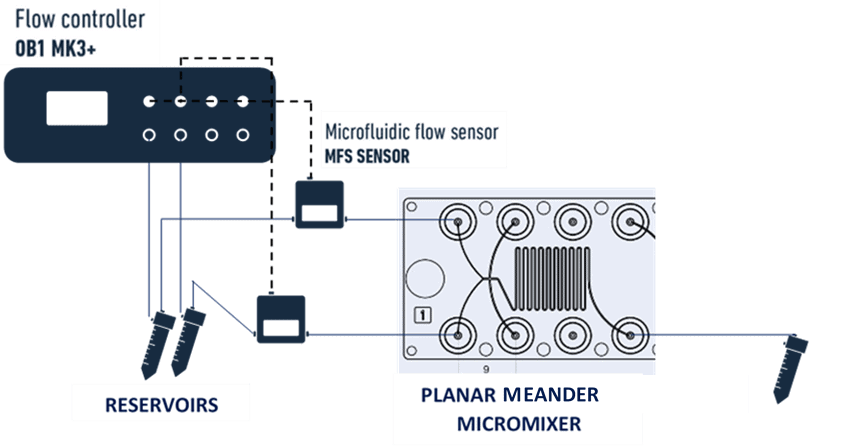

Based on the OB1 flow controller (Elveflow) and a planar meander mixing chip, this all-in-one solution contains all the required pieces for researchers to set up their mixing system with a high flow rate and mixing efficiency. Our microfluidic expert will accompany you during all the steps needed to setup and perform your micromixing experiment.

A standard multi-fluid mixing serpentine planar micromixer Pack contains pumping channels to push at least two fluids to mix through the serpentine micromixer chip, allowing the rapid creation of a homogenous fluid at the outlet of the chip by inducing a speed gradient in the channel.

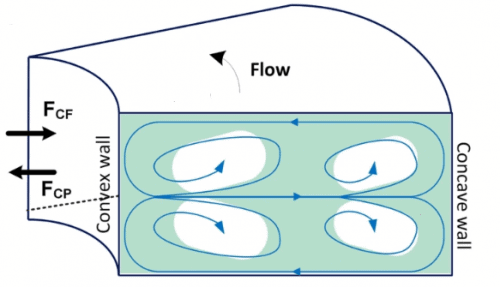

The fluid circulating in the serpentine-shaped channel is faster near the outer walls of the microchannel than the fluid circulating near the inside walls of the channels, thus inducing the creation of vortices, which allows the mixing of the different fluids inside the microchannel.

The efficiency of the mixing will be directly linked to the fluid’s properties and the flow rate inside the channel. Flow rates are precisely tuned by the OB1 flow controller and can be measured by flow rate sensors like the MFS or the BFS series (Elveflow).

Serpentine micromixer pack setup

An all-in-one pack guaranties a good compatibility between the different microfluidic instruments and accessories, allows the start the experiment right out the box, is piloted by a single software and can be used for other different applications. These highlights pushed us to assemble this Pack for beginner and expert users.

A typical pack contains:

- OB1 flow controller (Elveflow)

- 2x flow sensors MFS (or BFS flow sensor) (Elveflow)

- Falcon reservoirs

- Microfluidic chip from microfluidic ChipShop

- All necessary accessories: tubing, connectors, filters, etc…

- Command and automation software (Elveflow)

Why use microfluidics for fluid mixing

Microfluidics uses tiny volumes of sample which is very efficient to decrease the amount of expensive sample needed for experiment.

Moreover, at the microfluidic scale fluid properties can be precisely tuned and very fast kinetics is possible which is important for crystallization and precipitation processes for synthesis of polymeric nanoparticles for example.

Microfluidics also enable to precisely control reactions in the micromixer by adding specific reagents at specific moments during the experiment.

Micromixers allow the reaction to isothermal thanks to the increased heat transfer in microreactors.

Since planar serpentine micromixers are miniaturized, this mixing part can be implemented in a more complete experiment platform to perform complicated and multifunctional integrated process.

To summarize, micromixers chips allow more flexible, precise and efficient mixing between two fluids.

- Nivedita, Nivedita, Phillip Ligrani, and Ian Papautsky. “Dean flow dynamics in low-aspect ratio spiral microchannels.” Scientific Reports 7.1 (2017): 44072.

Microfluidics serpentine micromixer principle

Mixing is a crucial step in a lot of different microfluidic applications [1]. The planar serpentine micromixer (PSM) chip creates mixing because of a liquid speed difference in the turns between the inner and the outer wall improving the mixing [2]. The mixing by diffusion in a straight microchannel is too slow to be useful in microfluidics setups as a typical flow in microfluidics setups is laminar and consequently without the turbulence that induces mixing.

This design creates a transversal advection for intermixing different components in the microchannel [3-4]. Indeed, the PSM chips are an effective and straightforward way to mix without using any external power source and thus can be modeled more efficiently than more complex techniques [5].

Micromixing using a serpentine micromixer can be helpful and an improvement for various applications like combinatorial or organic chemistry, handling hazardous substances, PCR, screening and many more [6-9].

References

- Lee, Chia-Yen, et al. “Microfluidic mixing: a review.” International journal of molecular sciences 12.5 (2011): 3263-3287.

- Nivedita, Nivedita, Phillip Ligrani, and Ian Papautsky. “Dean flow dynamics in low-aspect ratio spiral microchannels.” Scientific Reports 7.1 (2017): 44072.

- Nguyen, Nam-Trung. Micromixers: fundamentals, design and fabrication. Micro & nano technologies. William Andrew (2011).

- Scherr, Thomas, et al. “A planar microfluidic mixer based on logarithmic spirals.” Journal of Micromechanics and Microengineering 22.5 (2012): 055019.

- Kee, Suet Ping, and Asterios Gavriilidis. “Design and characterisation of the staggered herringbone mixer.” Chemical Engineering Journal 142.1 (2008): 109-121.

- Wilms, Daniel, Johannes Klos, and Holger Frey. “Microstructured Reactors for Polymer Synthesis: A Renaissance of Continuous Flow Processes for Tailor-Made Macromolecules?” Macromolecular Chemistry and Physics 209.4 (2008): 343-56. Print.

- Zhang, Chunsun et al. “Micropumps, microvalves, and micromixers within PCR microfluidic chips: Advances and trends.” Biotechnology advances vol. 25,5 (2007): 483-514.

- Dittrich, Petra S et al. “Micro total analysis systems. Latest advancements and trends.” Analytical chemistry vol. 78,12 (2006): 3887-908.

- Dittrich, Petra S, and Andreas Manz. “Lab-on-a-chip: microfluidics in drug discovery.” Nature reviews. Drug discovery vol. 5,3 (2006): 210-8.

Customize your microfluidic serpentine micromixer

The planar serpentine micromixer chip provided by Microfluidics ChipShop is available in Polycarbonate (PC) or Cyclo Olefin Copolymer (COP) materials, channel depth: 100 µm; channel width inlet: 100-200 µm; channel width mixer: 200 µm; channel width outlet: 200 µm. The efficiency of the mixing depends on the Reynolds and the Peclet number. For advice on a specific application, contact one of our experts!

Up to 4 fluids can be mixed using the microfluidic serpentine micromixer pack with the same microfluidic chip and four OB1 flow controller active channels. Consequently, additional flow rate sensors can also be provided.

Coriolis flow sensors can be chosen to replace the MFS to improve the flow control even more.

Bubble can be a problem when mixing; bubble remover that can tackle this issue can be provided if this issue is critical for the experiment.

Substance mixing can also be achieved with other strategies like herringbone micromixers.

Contact our experts for any questions about this fluid mixing pack and how it can match your specific application.

– Check our other Packs for various applications –

How can we help your experiment

The packs applications are still under development, so we are not able to give you the tips or troubleshooting advice that we usually give in our user guides and application notes for the possible challenges you could face for a specific application experiment. That being said, we can always guarantee reliable and high-precision microfluidic flow control. Our microfluidic instruments are high-performance, versatile and user-friendly. Our experts will bring support and expertise during the setup and implementation of this sensor calibration pack.

Can a pack be customized

Yes! Our experts will establish which instruments are best suited for your application, such as the type of flow sensor or the number of flow controller channels you need to perform your experiment. Drop us a line at innovation@microfluidic.fr.

Can I buy individual instruments?

You can order our instruments on the product section of our website.